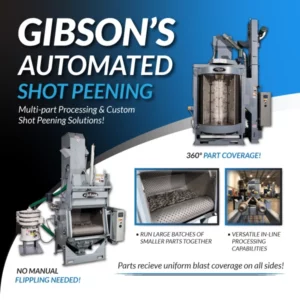

Shot peening involves the stress relieving or hardening of part surfaces to resist fatigue and prolong service life. Gibson’s Tumble Blasters and Dual Chamber Spinner Hangers process work-pieces through automated blast cycles, which ensures uniform blast coverage over surfaces. These versatile machines enable large batches of complex parts to be peened on all sides, especially heavily contoured surfaces.

Shot peening involves the stress relieving or hardening of part surfaces to resist fatigue and prolong service life. Gibson’s Tumble Blasters and Dual Chamber Spinner Hangers process work-pieces through automated blast cycles, which ensures uniform blast coverage over surfaces. These versatile machines enable large batches of complex parts to be peened on all sides, especially heavily contoured surfaces.

Gibson 3BB Wheel Blast Tumbler

Gibson Tumble Blasters process multiple parts, ranging in size from small to medium, with a level of speed and efficiency unmatched by other types of equipment in a comparable price range. The operator loads parts onto a rugged perforated belt, closes the loading door, sets the timer and pushes the start button. By tumbling parts within the blast envelope, these machines deliver consistent results automatically whether working intermittently or non-stop in a multi-shift production facility.

Gibson 3BB Wheel Blast Tumbler with Optional Loader

Gibson 24×60 Dual Chamber Spinner Hanger System

Gibson Spinner Hangers provide an ideal solution for batch blasting many types of parts too fragile or awkward for other methods of automated finishing. These systems play a profit-boosting role across a broad range of metal-intensive industries by improving quality and efficiency during peening of almost any work-piece suitable for mounting on hooks.

Our systems include two work chambers mounted on an indexing turntable. As the turntable steps through programmed positions, one chamber exposes parts to a contained blast stream emanating from high-efficiency wheels while the other opens to the operator, who loads and unloads parts from the un-contained chamber. To assure uniform coverage, a spindle rotates the hangers within the working chamber’s blast envelope.

Gibson Custom In-Line Shot Peening System